Close

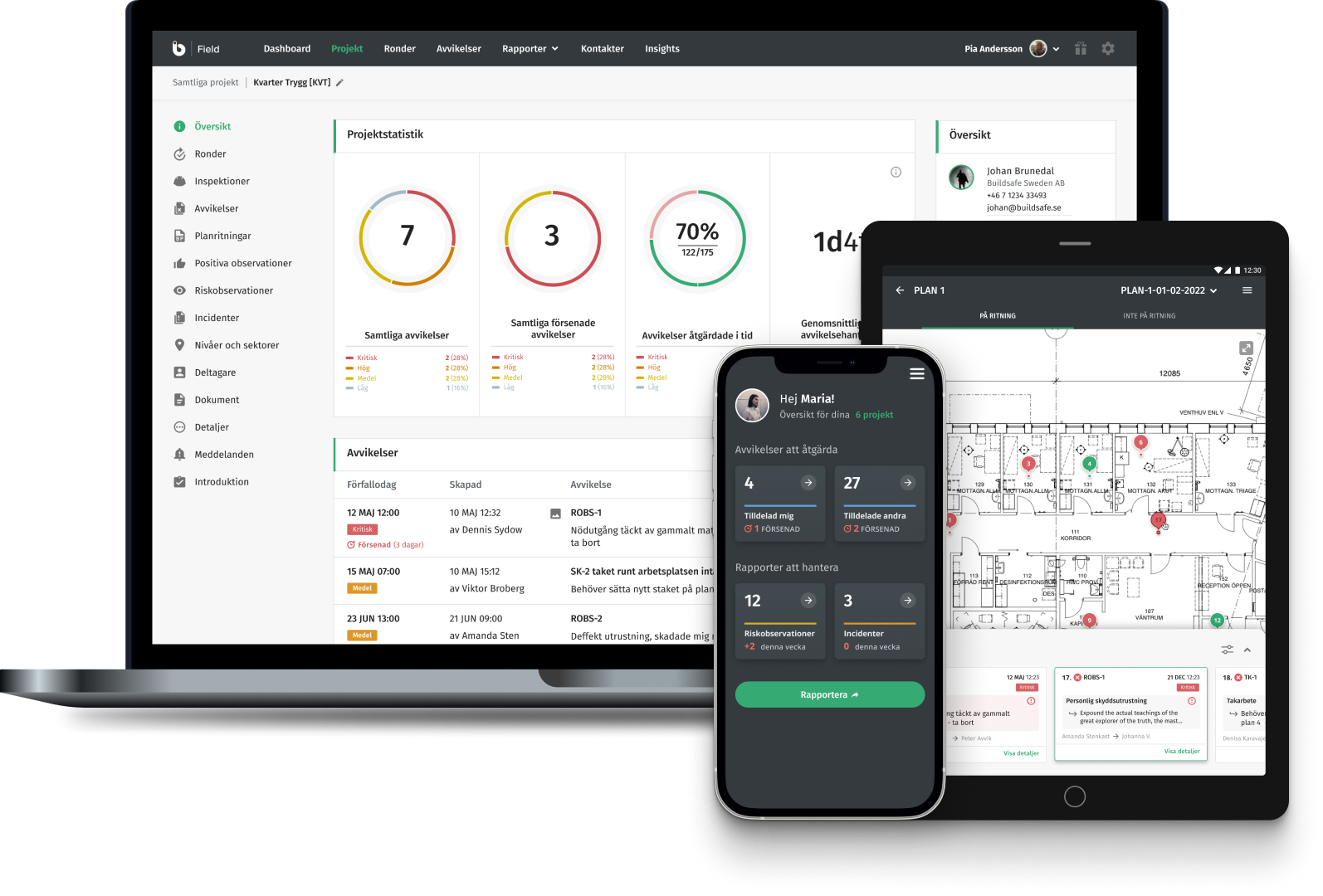

Infobric Field

Manage your site

Site inductions

Smooth and easy online registration

Ad-hoc reporting

Enables everyone on site to report observations and incidents

Inspections

User-friendly tools for combining checklists, forms and controls

Deviation management

Full control on site with bespoke task lists updated in real-time

Insights

Automated analysis and visualisations of trends and KPI’s

Investigations

Investigations of Near Misses and Accidents to map out and identify root causes and sources of risk.

User-friendly QHSE-platform to manage your site

Infobric Field

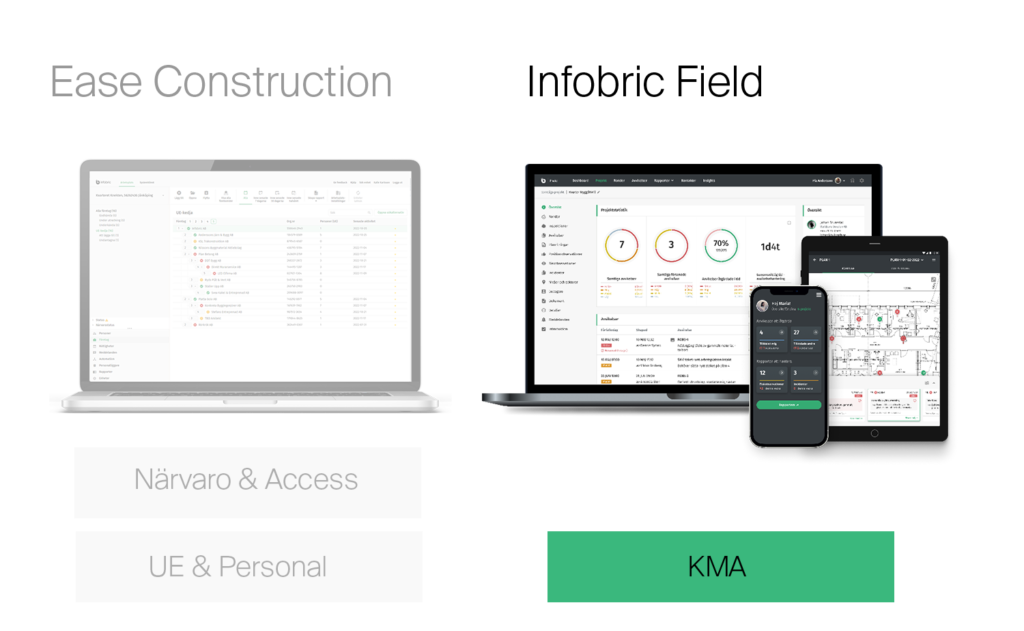

Infobric offers a variety of digital services and smart functions that help you keep track of individuals, companies and QHSE. The services are available on the Ease Construction and Infobric Field platforms. Via Ease Construction you use the services in presence, access, UE and personnel. Via Infobric Field, services are offered within QHSE. With Infobric Field you ensure that:

- Everyone understand and communicate requirements.

- Anyone can report risks

- The right checks are made at the right time

- All identified deficiencies are addressed

- You can evaluate and analyze results

Benefits of Infobric's QHSE platform

Get started quickly

Easy to get started with user-friendly features that adapt to role

Flexibility

Great flexibility in adapting processes and templates to suit your way of working

Focus on results

Results-focused platform with a unique focus on reducing action times and driving individual responsibility

Decision basis

Visual aids to see status, analyze trends and compare performance

More observations

>

0

%

Faster actions

0

%

Fixed

0

%

Fewer incidents

>

0

%

”

Züblin

"Infobric Field helps us create a safer workplace. We get more eyes on the workplace and risks that I don't see are raised in a completely different way."

- Christine Johansson, Health & Security Manager

Our customers

Get answers to your questions

Frequently asked questions.

How do I start a project in Infobric Field?

As an existing customer, you can either fill out our form for project start-up or contact your contact person. If you do not have a central agreement, you can fill in the form to be contacted by sales.

How do I register for my project?

To access the registration form, you can either scan a QR code or use the link created for the project - contact your project for the correct information. Once you have access to the form, you can follow this guide: How does enrollment in the workplace introduction work?

How do I download the app?

Download the Infobric Field mobile application from the AppStore or Google Play. You can access the web platform at app.infobricfield.com.

How do I report an incident?

Click Report in the menu in our mobile app, or do it under Incidents in the project view on the web. All users have the right to report observations and incidents. When a person in charge has handled the report, an email will automatically be sent out to the reporter.

How do I start an inspection?

Inspections are done via our mobile app. If you have a scheduled inspection, it is visible under the home screen in the app. If it is not scheduled, you can do so via the plus sign in the menu. Read more details here: How do I complete a tour?